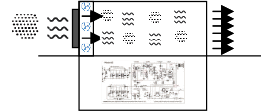

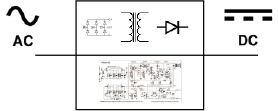

Our rectifier power modules are fully controlled by a microprocessor that runs all parameters in real time and gives dynamic adaptation of the load conditions in order to optimize output.

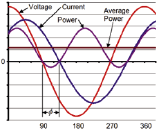

High frequency IGBT technology gives higher levels of efficiency than older SCR systems in all load conditions.

Weights and dimensions are reduced because costly rephasing systems no longer have to be fitted, and a notable energy saving is guaranteed thanks to the higher efficiency.

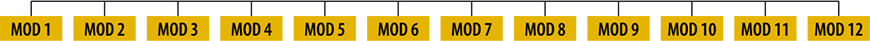

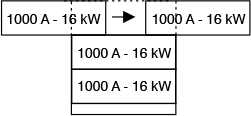

All the rectifier parts are interconnected by a high speed CANBUS digital network, therefore each module works independently from the others and can be replaced, added or eliminated.

This means that the end configuration of the machine is exceptionally flexible.

Extremely high powered rectifiers can be configured by simply connecting several machines together to create a single control.

Power modules of our rectifiers are totally controlled by a microprocessor that manages in real time all the parameters and allows a dynamic adaptation of the loading conditions in order to optimize the power supply.

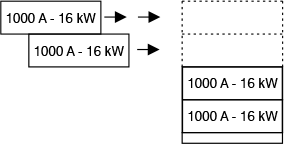

People usually believes that the construction using separate modules, represents a “modular” rectifier. Actually from the point of view of the supplied current this is not wrong, but remains unresolved the rectifier’s communication and control problems depending on an extra hardware (the control module) whose failure makes the rectifier totally unusable.

The disadvantage points are several:

- limited use of modules in function of the best capacity of the control module;

- assistance essentially delegated to producer;

- possibility to connect in parallel more rectifiers with only one current control;

- control hardware failure with the stopping of the entire rectifier.

The replacement operation of a faulty module takes 10 minutes and can be made by a normal technician, all the connections are plug and play, with removable connectors (movie www.powerel.it)

It clearly remains confirmed the availability of traditional control panels DE100, DE200 touch screen, and the connections MODBUS-RTU, PROFIBUS, PROFINET, etc.

|

Energy saving | The combination of the lowest energy consumption and the better metal deposition allow savings from 15% to 40% compared to traditional rectifiers. |

|

Flexible power | It is possible to increase, remove or simply switch off the modules according to need |

|

Space reduction | The layout of a modular rectifier is constructively less of 40% compared to a traditional one. |

|

Separation of electronic parts | In each module the forced air is filtered at the entrance and is never in touch with the electronic parts. |

|

Ripple content | The residual ripple measured is less than 2% (1% on request). |

|

Phase shift (Cos Ř) | Phase sift is 0.99 so it does not require systems of rephasing. |

|

Independent modules operation | Each module is independent of the others and can assume both master and slave configuration. If in slave configuration can be turned off and dispensing is guaranteed by the other modules. The master can never be off, but a slave can become a master. |

|

Electronic card replacement | Each module has only one electronic card with all the functions of the rectifier. The replacement is a lot easy and can be done by a normal maintenance technician. Movie on www.powerel.it |

|

Power module replacement | It is also easy to replace an entire module by a normal maintenance technician. Video on www.powerel.it |